Cuplock Scaffolding System Manufacturer & Supplier in India

Cuplock Scaffolding System Manufacturer & Supplier in India | Tejus Centering

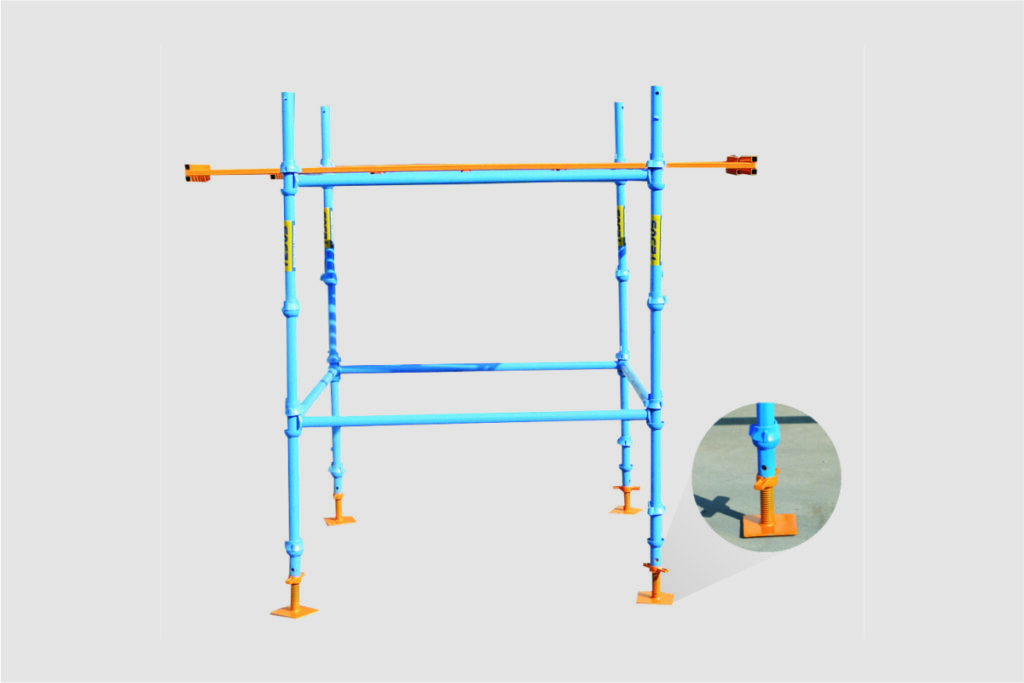

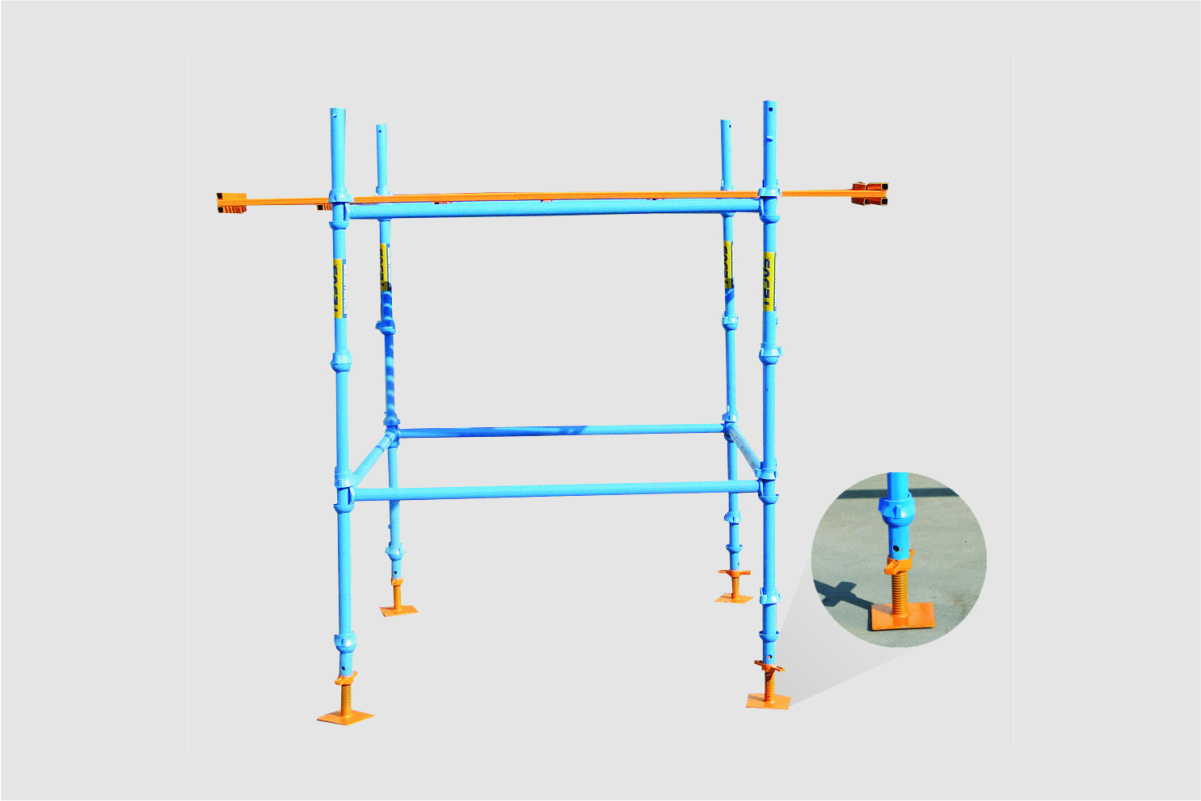

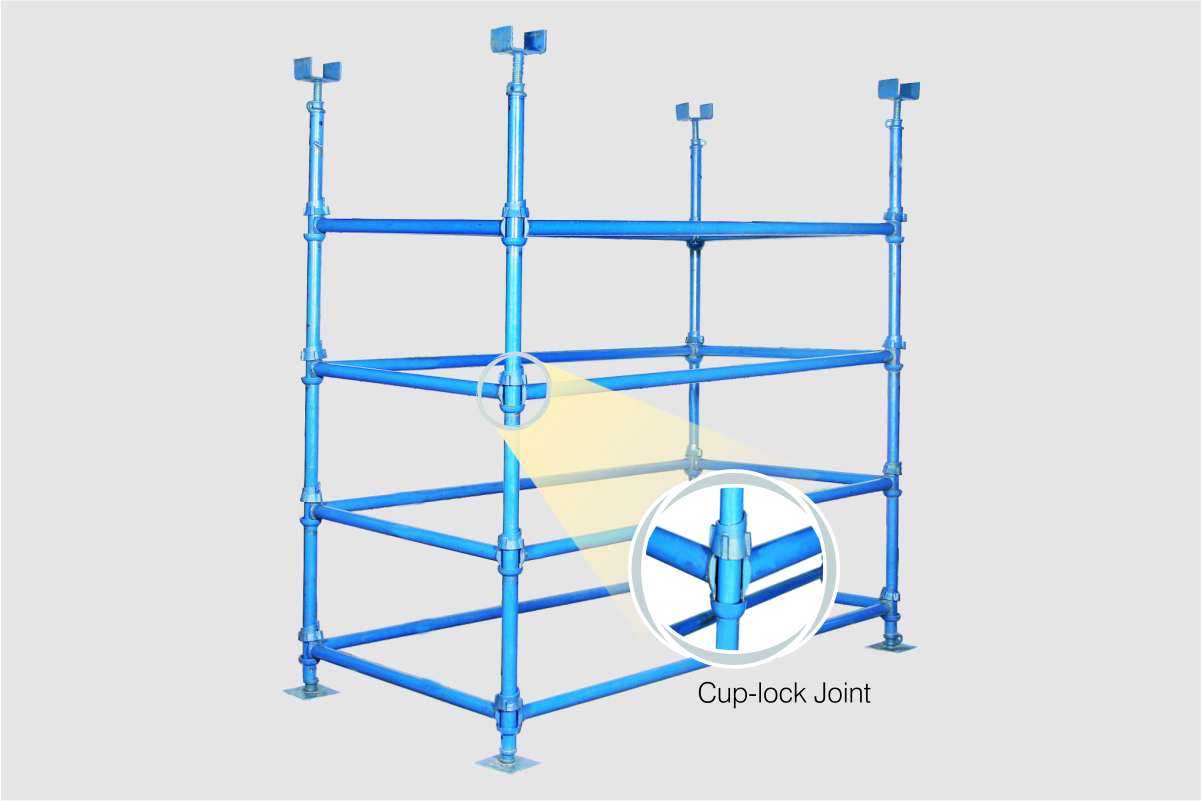

Tejus Centering is a leading manufacturer and supplier of Cuplock Scaffolding Systems in India, catering to construction projects across Pune, Maharashtra, Goa, Karnataka, and other regions. Our Cuplock scaffolding system is a versatile and multi-purpose solution widely used for plastering, supporting heavy structures, hoist machines, and access scaffolding. Designed for ease of use, this system can be quickly erected on straight, circular, and curved structures without requiring specialized tools, making it ideal for fast-paced construction sites. Even unskilled laborers can assemble it efficiently, saving time and costs.

The Cuplock system comprises vertical and horizontal members. Vertical members feature malleable cast iron cups that securely lock 40 NB pipes, with forged blades welded on both corners for added strength. This welded construction, combined with heavy-duty cross bracings, provides excellent rigidity and safety during use. The robust design makes it perfect for high slabs, bridge girders, heavy load staging, and support centering.

At Tejus Centering, quality assurance is paramount. Every Cuplock scaffolding component undergoes rigorous testing to ensure durability, strength, and compliance with international standards. Our systems incorporate the latest innovations in engineered scaffolding and formwork, trusted by leading construction companies across India.

We understand the unique challenges of the construction industry and are committed to supplying reliable, cost-effective scaffolding solutions that enhance site productivity and safety. Whether your project involves high-rise buildings, infrastructure development, or complex architectural forms, our Cuplock scaffolding systems provide the dependable support you need.

Choose Tejus Centering for premium Cuplock scaffolding systems that combine innovation, strength, and ease of use. Contact us today to discuss your requirements and experience unmatched quality and service.

Production Capacity – 200 Tons/month

Horizontals

Specifications

| Product Code | Length C / C | Weight |

|---|---|---|

| T905 | 2.0m | 6.8kg |

| T906 | 12m | 4.0kg |

| T907 | 1.5m | 5.0kg |

Cuplock System Scaffolding Manufacturer & Supplier in India | Tejus Centering

Tejus Centering is a top manufacturer and supplier of sturdy, durable Cuplock System scaffolding in Maharashtra, India. Our high-quality cuplock joints securely hold scaffolds together, ensuring safety and reliability. Trusted by builders, Tejus delivers robust scaffolding solutions tailored for diverse construction needs across India.

Spigots

200/300 mm long for making vertical connections.

These spigots are drilled with Two Holes to receive locking pins / Nut Bolting.

Specifications

| Product Code | Length C / C | Weight |

|---|---|---|

| T914 | 0.3m | 0.8kg |

Note: 3 mm thick 38 OD pipe.

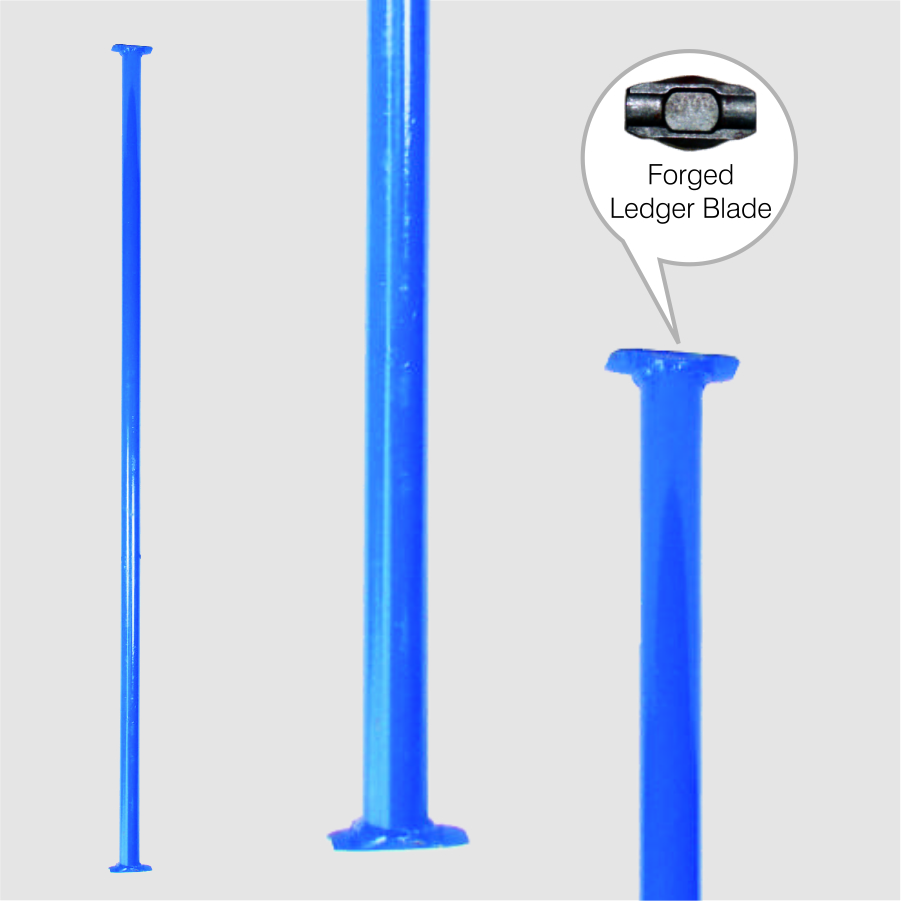

Note: Pipe as per BS 4360 N.B.M.S.Pipe OD 48.3 mm, Wall thickness 2.9 mm, Weight 3.25 Kg/m forged blade grade ‘2’on other side. As per requirement Verticals are tailor made.

Verticals

Verticals are provided in four basic sizes with cup joints welded at 500 mm, intervals. The captive top cups are of malleable casting to endure rough site handling, and welded bottom cups are pressed from high-quality steel.

Specifications

| Product Code | Length C / C | Weight |

|---|---|---|

| T901 | 3.0m | 14.97kg |

| T902 | 2.5m | 12.97kg |

| T903 | 2.0m | 10.00kg |

| T904 | 1.5m | 7.4kg |

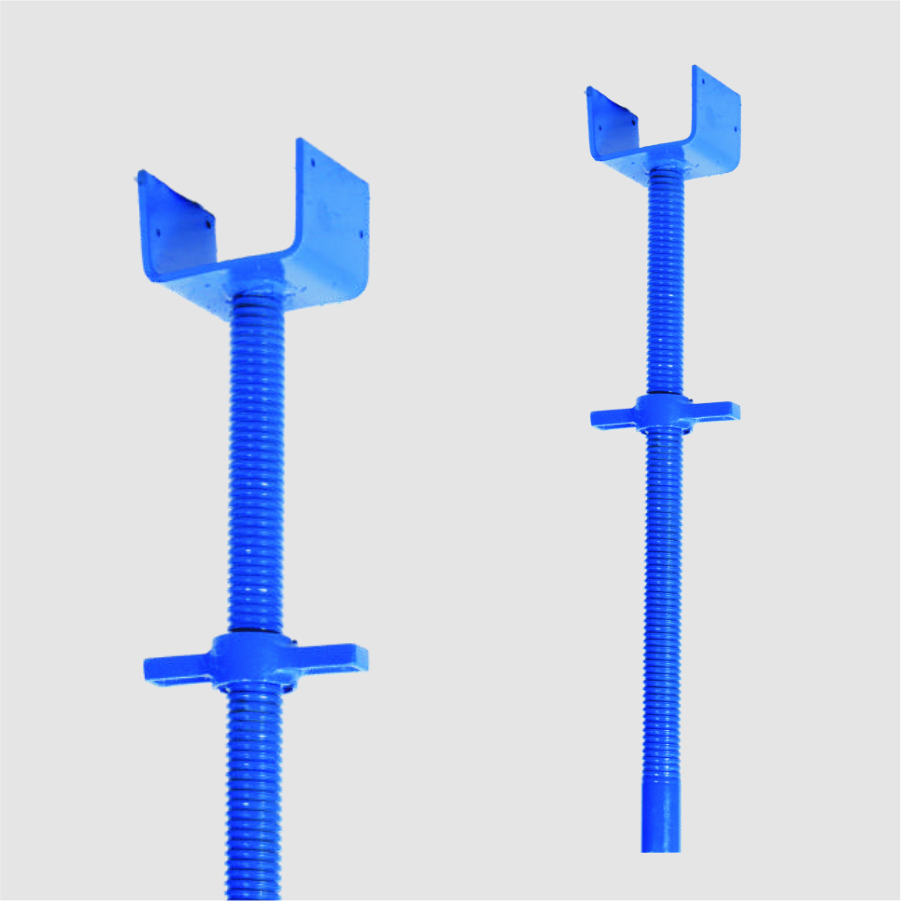

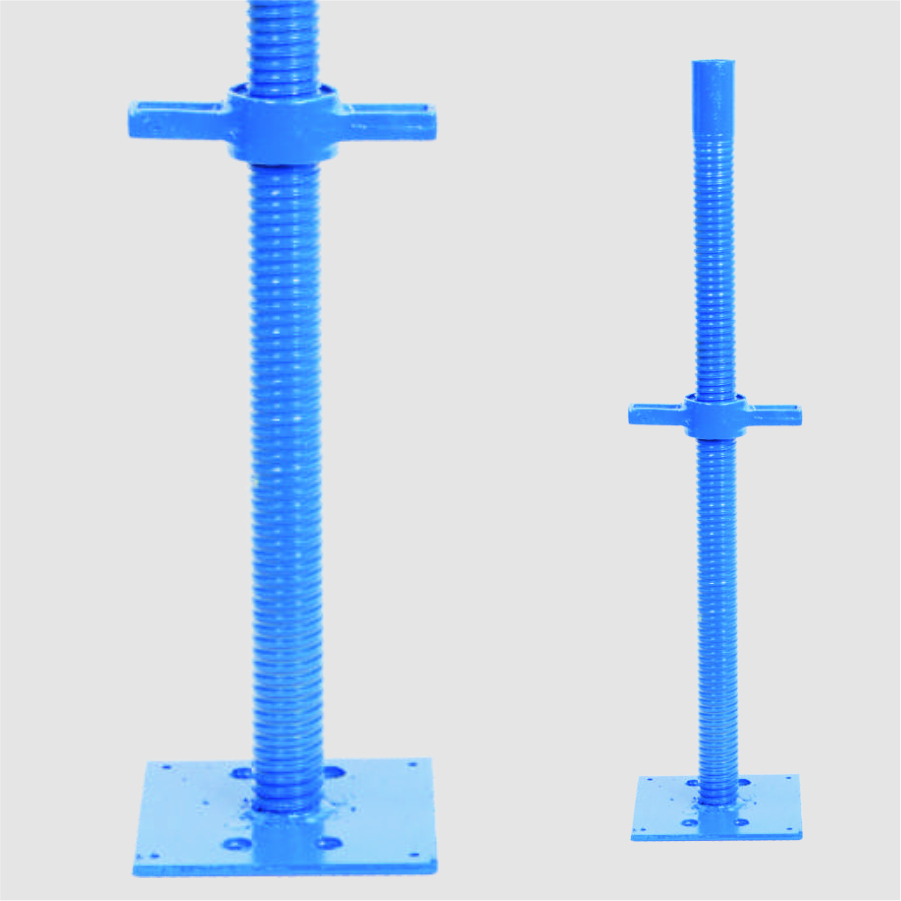

Adjustable Stirrup Head / Base Plates / Universal Jack

Tejus Centering manufactures and supplies high-quality Cuplock Scaffolding Systems in India, crafted using the thread rolling process on solid bars (32/36 mm) or hollow pipes (38 mm diameter, 4 mm thick). Our cuplock components come with various attachments, including a ‘U’ head (70x110x70 mm), base plate (150x150x6 mm), or universal jacks without attachments. Available in lengths of 350 mm, 450 mm, 650 mm, or custom sizes, these parts enable precise height adjustment at the top or bottom of scaffolding setups. The top cup is made of durable malleable cast iron with 3 or 4 lugs, the bottom cup is 4 mm press metal, and the ledger blade is forged from special steel, ensuring strength and reliability for construction projects nationwide.