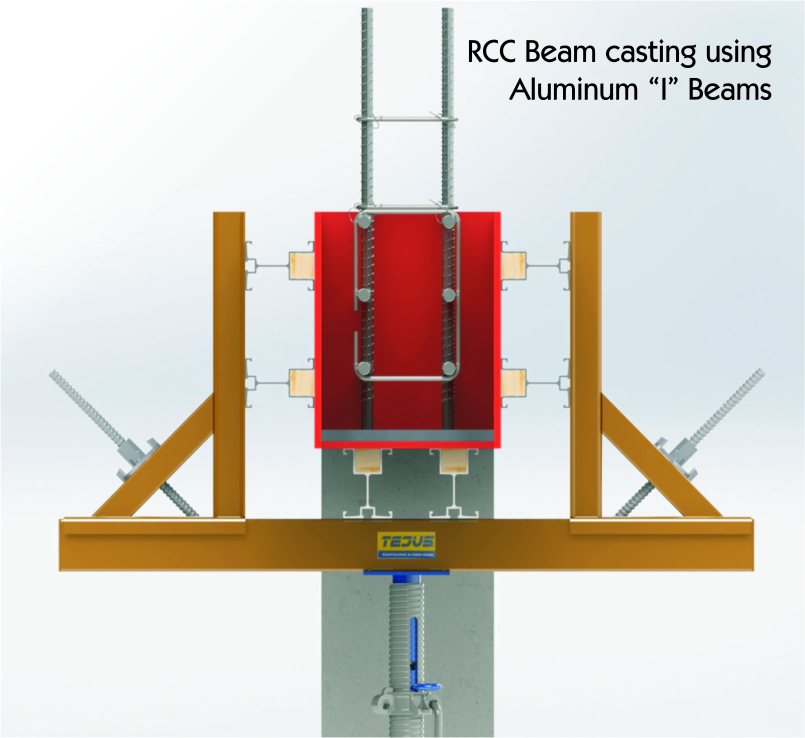

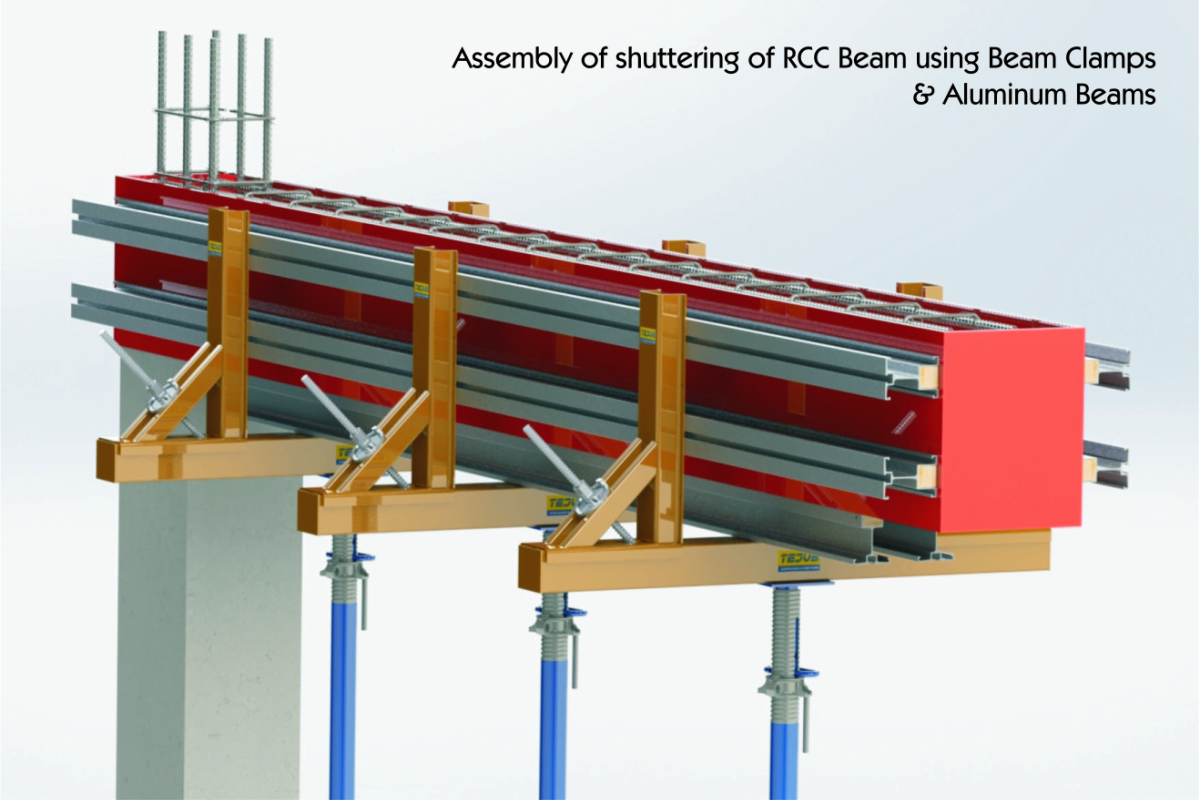

Aluminum Beams & Clamps for RCC Beam Formwork

Aluminium Beams & Clamps for RCC Beam Formwork | Tejus Centering India

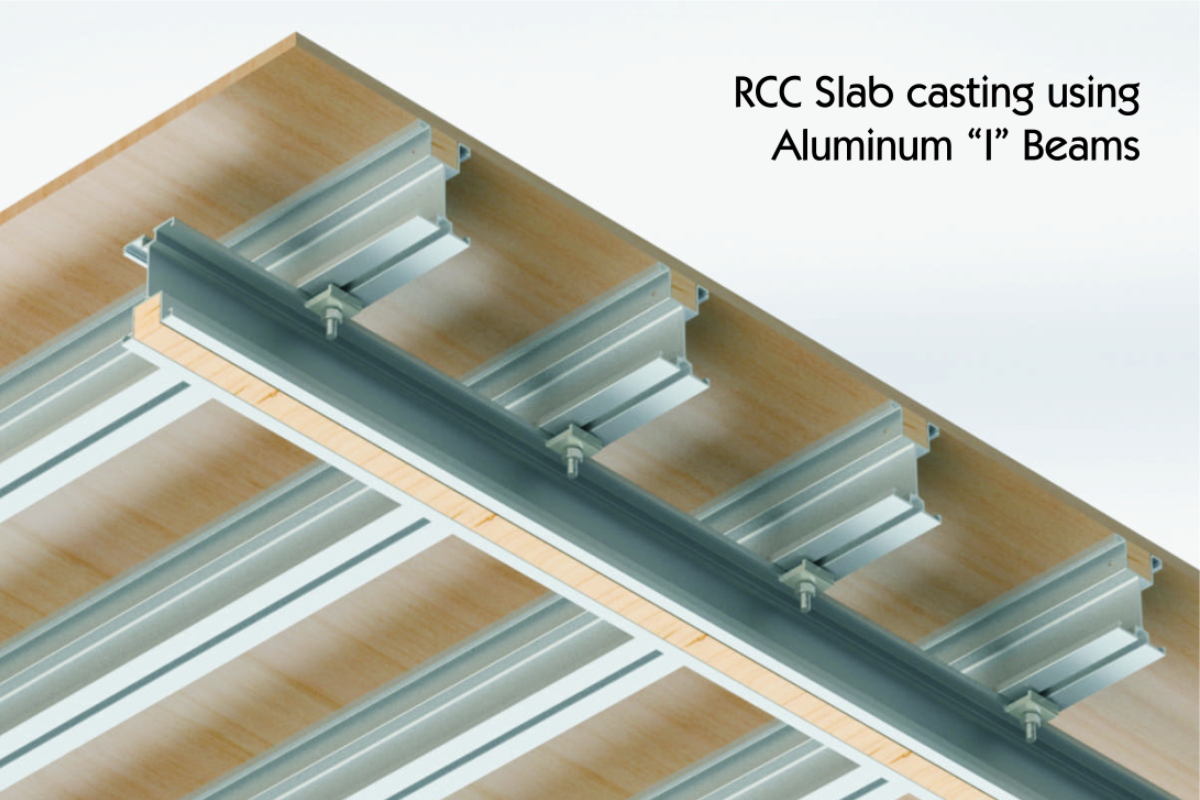

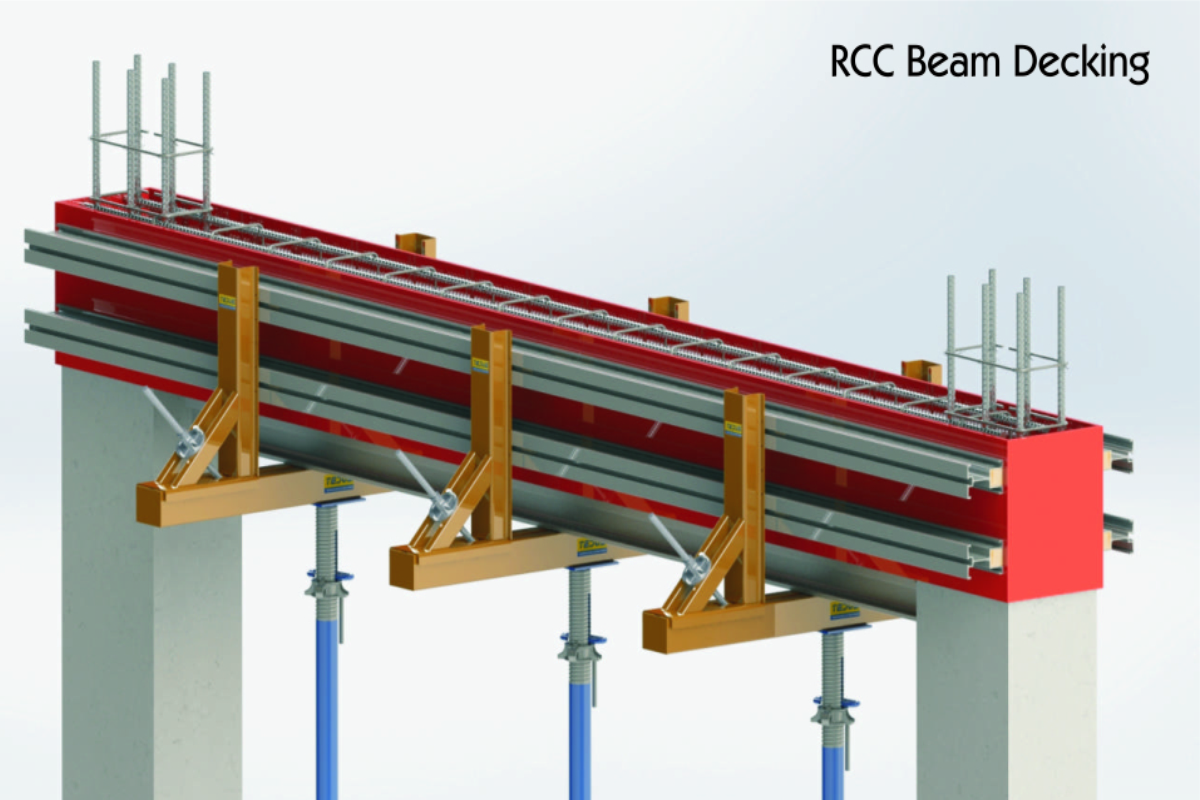

Tejus Aluminium Beams are the ideal solution for RCC beam and slab formwork, offering unmatched strength, versatility, and ease of use. Manufactured from high-grade structural aluminum alloy, these beams provide superior strength-to-weight ratio compared to traditional MS beams, square tubes, or H-20 beams.

The integrated T-bolt slot allows for fast and accurate alignment during erection, reducing labour time and enhancing on-site efficiency. A wood insert channel allows easy nailing or screwing of plywood decking, making the beams compatible with a wide range of shuttering applications.

Lightweight, rust-free, and reusable over many cycles, Tejus aluminium beams are economical, safe, and highly efficient. When paired with precision-engineered beam clamps, they ensure firm support and alignment for high-performance RCC formwork systems.

Advantages of Aluminium Beam & Formwork System

- Improved Productivity – Lightweight design enables faster installation and dismantling, speeding up site workflows.

- Environmental Protection & Energy Saving – Reusable aluminum components reduce timber use and overall site waste.

- Minimum Labor Required – Simple locking mechanisms and easy handling reduce manpower needs.

- Reduced Construction Cycle Time – Efficient system design cuts down slab and beam formwork time significantly.

- Highly Versatile – Compatible with various shuttering layouts, including RCC beams, slabs, and corewalls.

- Less Wastage of Plywood – Precision-fit assembly ensures minimal cutting and material loss.

- High Resale / Scrap Value – Aluminum retains great value post-use, offering strong returns on investment.

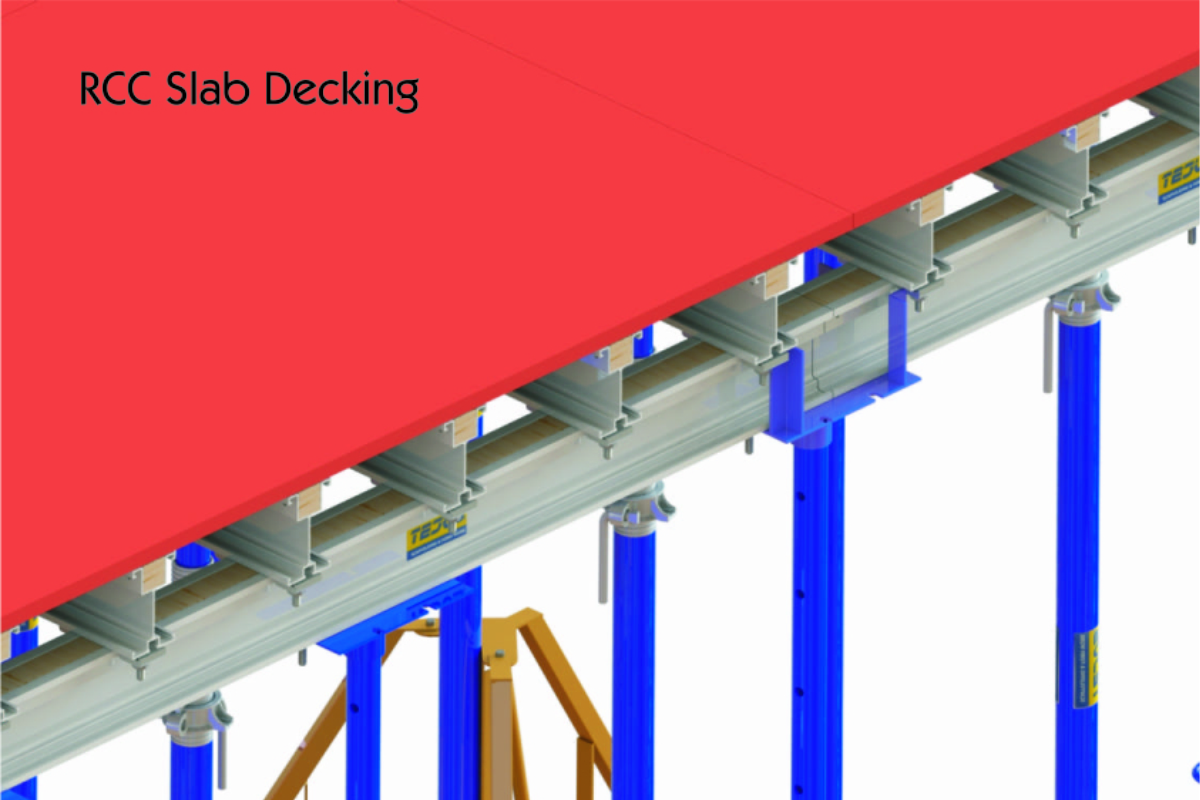

Aluminium Beams for RCC Beam & Slab Shuttering | Tejus Centering

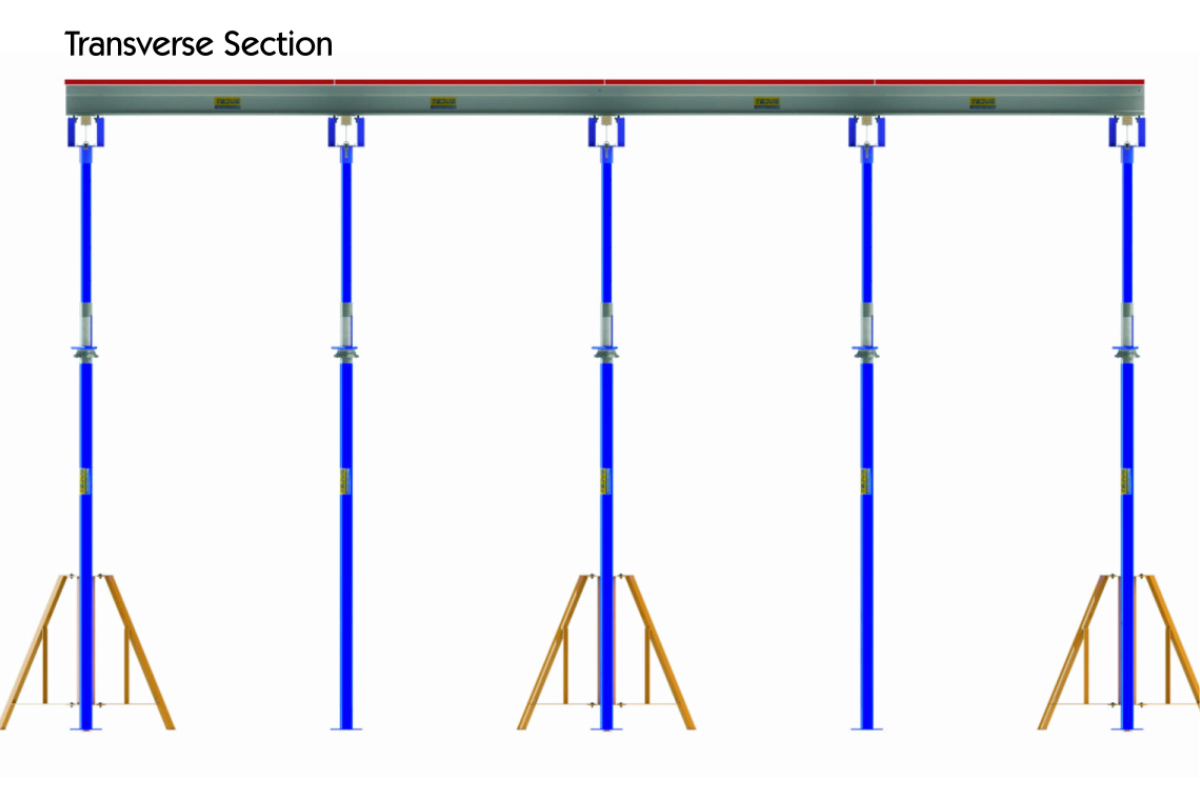

Use Tejus aluminium beams for RCC beam/slab shuttering with props, clamps, tripods & U-heads. Lightweight, strong & compatible with standard shoring systems.

Adjustable Props

Swivel Coupler

Weight : 0.8 kg

Forway Head

AL 120 Beam

Tripod

Weight : 11.0 kg

U Head

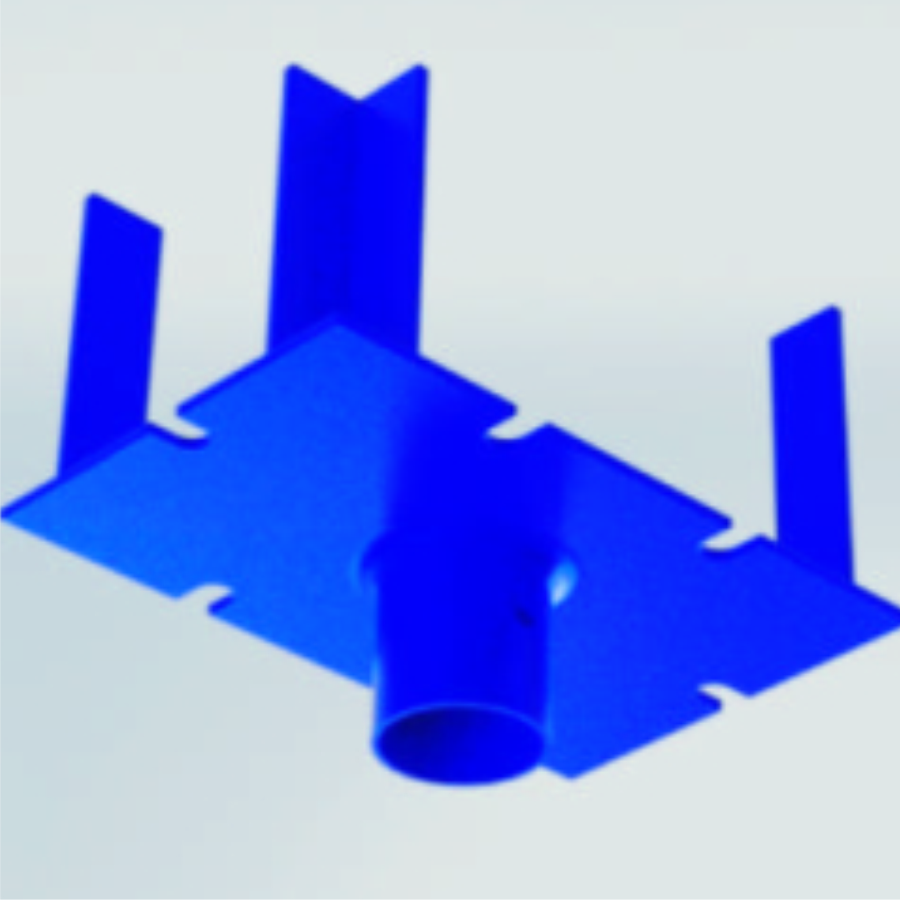

Beam Clamp

AL 140 Beam

Spacing Guidelines for 140 H-Beam Slab Formwork

Recommended Joist, Ledger, and Prop Spacing Based on Slab Thickness & Load

| SLAB THICKNESS (mm) | IMPOSED LOAD (Kpa) | JOIST SPACING (mm) | LEDGER SPACING (mm) | PROPS SPACING (mm) |

|---|---|---|---|---|

| 100 | 947 | 610 | 2000 | 2400 |

| 150 | 11.15 | 488 | 2000 | 1350 |

| 180 | 12.16 | 488 | 2000 | 1300 |

| 200 | 12.83 | 488 | 2000 | 1250 |

| 250 | 14.51 | 488 | 2000 | 1200 |

| 280 | 15.52 | 488 | 1800 | 1150 |

| 300 | 16.19 | 406 | 1800 | 1100 |

| 350 | 17.87 | 406 | 1800 | 1000 |

| 400 | 19.55 | 406 | 1600 | 1000 |

- Imposed Load is 1.4 DL + 1.7 LL, where LL is 50 Psf + 25 Psf Impact load

- The suggested ledger and props spacing may vary depending on the length of Josit and floor height

- Floor height considered in this analysis is 3.6 meters and length of Joist is 3.9 to 4.5 meters